History and Evolution of Coin Minting

The Birth of Coins: A Journey Through Time

Picture this: a bustling marketplace in ancient Lydia, roughly 600 BCE. Among traders exchanging goods and chattering away, glinting in the sunlight lies something revolutionary – the first true coin. Crafted from a mix of gold and silver known as electrum, these small stamped pieces of metal marked the start of an incredible journey. Coins transformed commerce, making complex bartering systems a thing of the past.

As centuries rolled by, the process of minting evolved. The Greeks turned it into an art form, producing coins adorned with intricate designs of gods, heroes, and mythical beasts. The Romans? They took it a step further, using coins as political tools – imagine holding a denarius stamped with the face of Emperor Augustus, a pocket-sized declaration of power.

Fast forward to medieval Europe. Coin production became a laborious craft. Blades sliced blanks, hammers stamped designs, and every piece felt like a miniature masterpiece. But don’t romanticize it too much – counterfeiters always lurked behind the scenes, chiseling away the edges of coins to steal precious metals!

- First coins: Ancient Lydia, approx. 600 BCE.

- Greek artistry revolutionized designs.

- Romans expanded minting for propaganda.

From Handcrafted Precision to Mechanical Marvels

The Industrial Revolution catapulted coin minting into a new era. Picture giant steam-driven presses clanking rhythmically as they churned out perfectly uniform coins. Suddenly, the days of manual hammer-striking seemed primitive. This was the dawn of mass production in minting, where precision met power.

Today’s coin-making process owes much to these breakthroughs, but it has also pushed boundaries with cutting-edge technology. Yet, think about this: isn’t it fascinating how, even after thousands of years, we’re still chasing that perfect balance between artistry and utility? From hand-struck wonders to machine-crafted marvels, coin minting continues to reflect the ingenuity of human hands and minds.

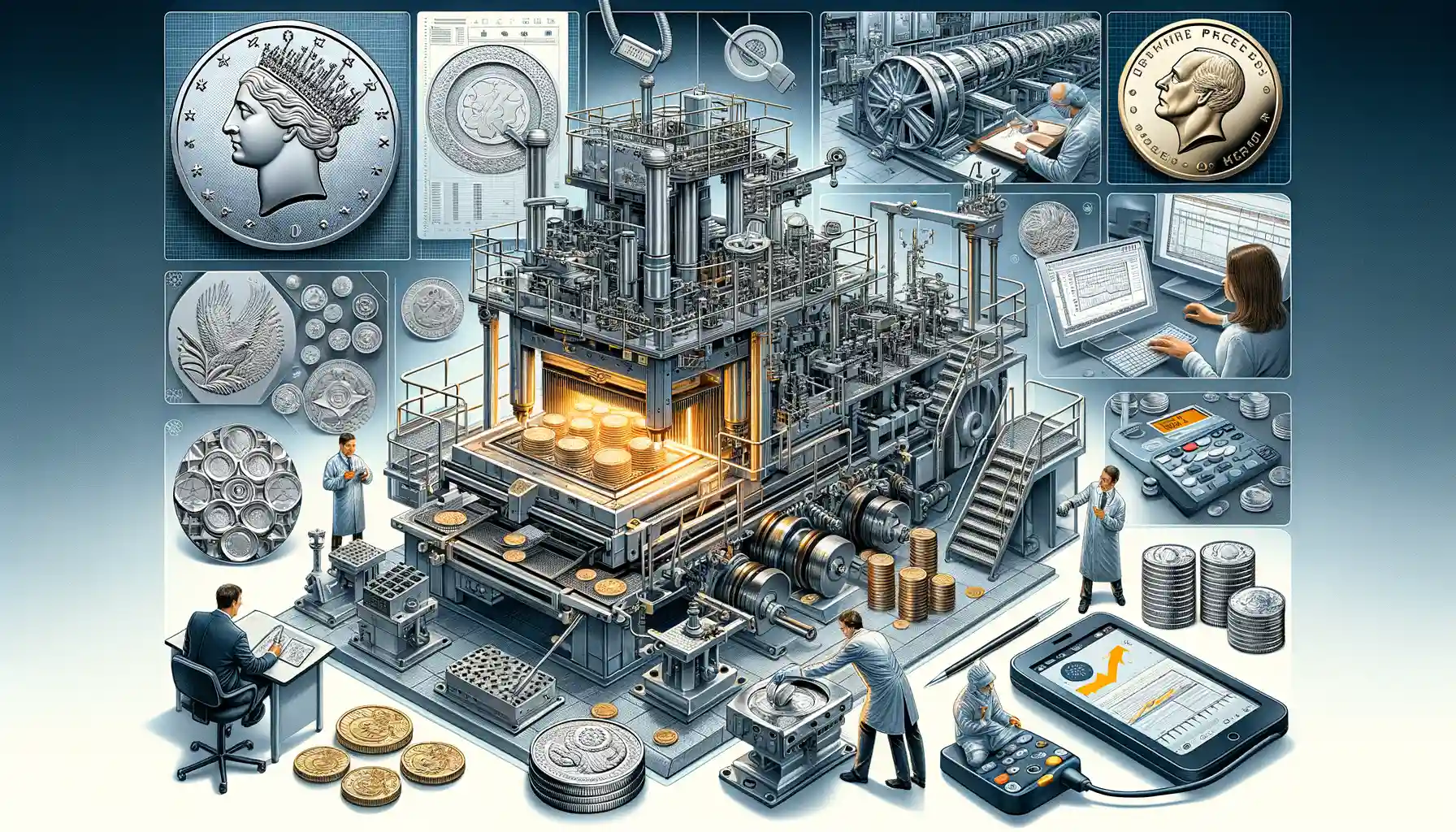

The Modern Minting Process Explained

From Blank Metal to Gleaming Treasure

Imagine holding a dull, lifeless piece of metal in your hand. It’s unremarkable, isn’t it? Now picture that same piece transformed into a glittering, detailed coin—a work of art infused with history and precision. This is the heart of modern minting: a blend of cutting-edge technology and age-old craftsmanship.

It all starts with blank metal discs, known as planchets. These unassuming circles undergo a process that can only be described as magic. First, they’re cleaned and polished until they gleam like mirrors. Then comes the real drama: the strike. A colossal press slams down with incredible force—sometimes up to 1,000 tons!—engraving intricate designs onto both sides of the planchet in milliseconds.

- Engraving: Master artisans create designs that celebrate culture, history, or heroes.

- Precision alignment: Each planchet must align perfectly to ensure flawless detailing.

It’s fascinating to think of the care involved in something so routine. Every time you hold a coin, you’re carrying a tiny masterpiece crafted with passion and precision. Now, doesn’t that change the way you see loose change?

Key Technologies Used in Coin Production

The Unsung Heroes: Machines and Methods Behind Coin Making

Ever wondered how a humble blank of metal transforms into a shiny coin that jingles in your pocket? It’s a fascinating blend of artistry and cutting-edge technology! Let’s peel back the curtain on the tools and techniques that bring coins to life.

First up, the coin blanks—these little circular canvases are precision-cut using state-of-the-art blanking presses. Imagine slicing dough for cookies, except everything is calibrated to microns! Once cut, these blanks need their moment of pampering. They take a luxurious bath in chemical solutions to scrub off impurities, leaving them gleaming like tiny silver moons.

Then comes the superstar of the minting process: the coin press. This powerhouse machine operates with jaw-dropping force—up to 100 tons of pressure! The design dies, engraved by skilled artisans, are pressed against the blanks, creating those intricate patterns we adore.

- Laser engraving: Adds hyper-precise details, like micro-text or hidden security marks.

- Edge lettering machines: Spin coins like records to adorn their edges with text or patterns.

It’s a dance of metal, mechanics, and mastery. Each step meticulously choreographed to ensure perfection in every single coin!

Challenges Faced in Coin Minting Today

The Hidden Struggles Behind Every Coin

Picture this: a glinting, perfectly circular coin in your hand. Seems simple, right? But behind its shining surface lies a storm of challenges that would make even the most seasoned minting expert raise an eyebrow.

First up, there’s the eternal battle of **material costs**. Precious metals like gold and silver aren’t exactly falling from the sky. Their prices fluctuate wildly, driven by unpredictable markets, wars, and global events. Mints walk a tightrope, balancing material expenses while ensuring coins don’t lose their intrinsic value.

Then comes the challenge of counterfeiting. In a world where tech-savvy fraudsters are always one step ahead, mints are locked in a never-ending game of cat and mouse. They pour resources into adding cutting-edge security features—think micro-engraving so fine you’d need a microscope to truly appreciate it.

Producing coins uses energy, a lot of it—raising questions about sustainability. Can minting evolve to have less environmental impact while meeting demand? That’s the million-dollar question.

Every coin may look effortless, but trust us, its journey to your pocket is paved with trials worth marveling at.

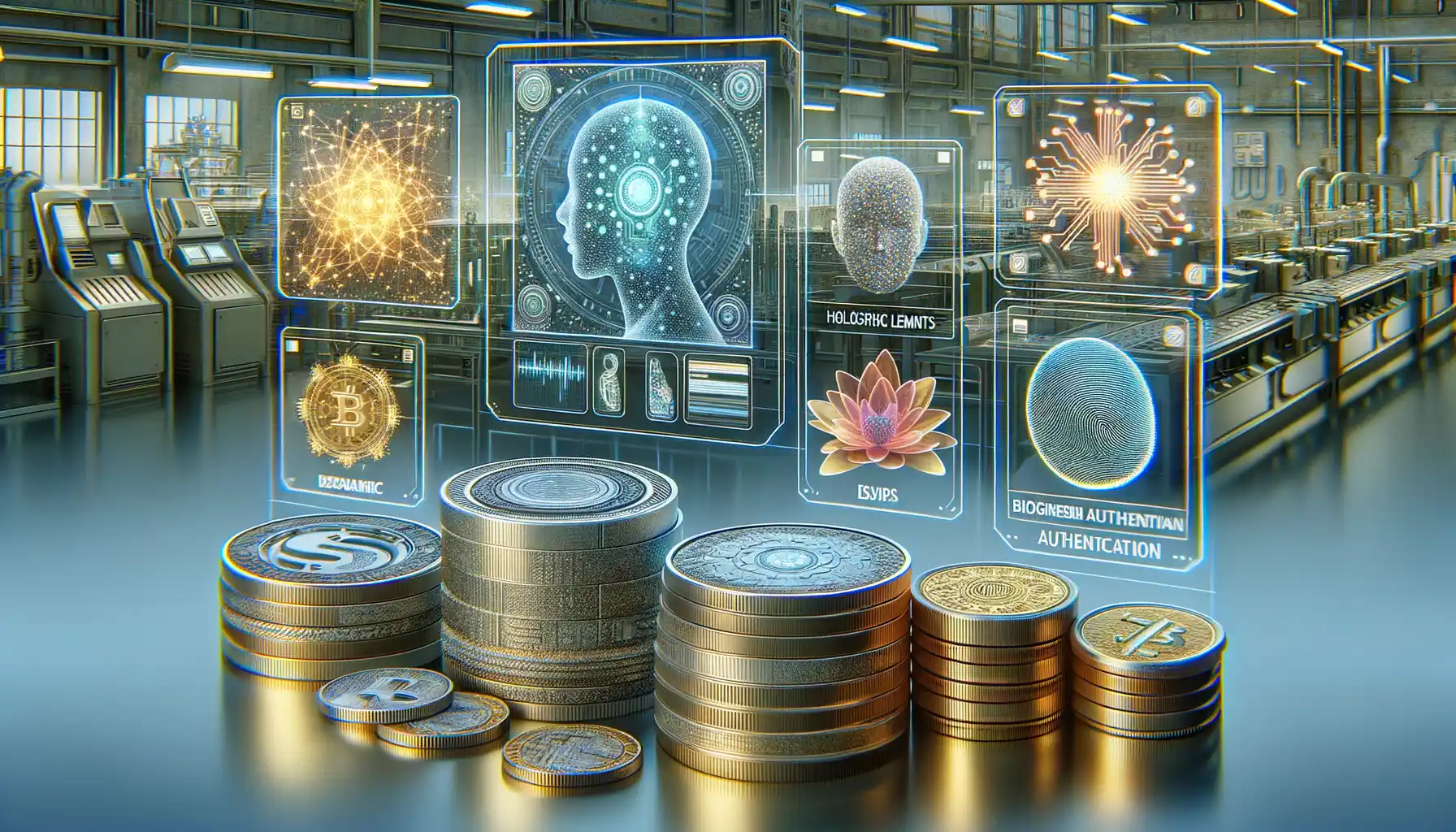

Future Trends in Coin Minting and Design

Reimagining Coin Design in a Digital Age

The future of coin minting is shimmering with possibilities, blending tradition and innovation like an artist mixing colors on their palette. Imagine coins that aren’t just metal discs but miniature works of art, pushing the boundaries of what we know today.

One trend already making waves is the integration of cutting-edge technology into coin design. Think augmented reality-enhanced coins, where scanning a coin with your smartphone reveals hidden stories of its origin—like unlocking a secret door to history. Another leap forward? Materials are evolving beyond silver and gold to include futuristic alloys and even sustainable options, giving coins a new shine while caring for our planet.

- Interactive designs that change under light or movement.

- Customizability for collectors—imagine creating coins with personal imprints or unique patterns.

The Fusion of Art and Security

Design isn’t just about aesthetics; it’s also becoming a technological armor against counterfeiting. Picture micro-details so intricate they require advanced magnification to even notice. Or, holographic patterns that shimmer in ways no forger could replicate. That’s where the future is heading—making coins not just beautiful but impenetrable fortresses of value.

This blend of art and tech will turn every coin into a conversation piece, a treasure worth holding close.